Background and Rationale

AU Member States recognize that sustainable agricultural mechanization is a key enabler of agricultural transformation, productivity growth, and inclusive agri-food systems development. However, Sustainable Agricultural mechanization in Africa remains fragmented, uneven, and under-coordinated, despite its central role in achieving food security, decent rural employment, climate resilience, and agri-food systems transformation. While many African countries have established national agricultural mechanization and engineering services, these institutions often operate in isolation, with limited opportunities for structured peer learning, harmonization of standards, or coordinated policy engagement at continental and regional levels.

At the same time, the Framework for Sustainable Agricultural Mechanization in Africa (F-SAMA) calls for strong national leadership, cross-country learning, and institutional coordination to translate policy commitments into practical, scalable, and sustainable mechanization solutions. The absence of a formal platform linking Heads of Mechanization and Engineering Services has constrained collective action, slowed uptake of good practices, and weakened Africa’s voice in global and continental mechanization discourse.

The HAMES Network was therefore conceived as a continental professional and policy network that brings together Heads of Agricultural Mechanization and Engineering Services to strengthen leadership, coordination, and implementation capacity for sustainable agricultural mechanization across Africa. Member States supported its establishment as a continental platform that connects senior government officials and national expertise responsible for agricultural mechanization and engineering in African countries. The Network provides a structured space for peer exchange, policy dialogue, technical collaboration, and joint advocacy in support of sustainable, inclusive, and climate-smart mechanization.

HAMES Network serves as a bridge between continental frameworks and national implementation, supporting countries to operationalize F-SAMA, align mechanization actions with CAADP commitments, and leverage digital tools such as the AfricaMechanize Platform for knowledge sharing and decision support. It acts as a technical backbone for SAM implementation in Africa, linking policy to practice, strengthening engineering services, and accelerating adoption of sustainable, inclusive, and climate-smart mechanization pathways.

Core Objectives

- Strengthen institutional leadership and coordination of agricultural mechanization and engineering services in Africa

- Facilitate peer learning and exchange of best practices on mechanization policies, technologies, and service delivery models

- Support operationalization of F-SAMA at national and regional levels

- Promote harmonization of standards, guidelines, and approaches to sustainable mechanization

- Enhance Africa’s collective voice and visibility in continental and global mechanization initiatives

Expected Value Addition

The HAMES Network aims to strengthen institutional leadership and coordination of agricultural mechanization in Africa. Some of the key excepted value enhancement includes:

- Improved policy coherence and implementation effectiveness for agricultural mechanization

- Accelerated adoption of sustainable, climate-smart, and inclusive mechanization pathways

- Stronger linkages between policy, engineering services, private sector, and knowledge platforms

- Reduced duplication and enhanced south–south learning among African countries, thus strengthened Africa’s collective voice in continental and global mechanization initiatives.

Key Messages

In this space of SAM some of the key messages to note includes:

- Agricultural mechanization is essential for achieving CAADP targets and Africa’s agri-food systems transformation.

- Strong national leadership and cross-country coordination are prerequisites for operationalizing F-SAMA.

- Heads of Agricultural Mechanization and Engineering Services are critical change agents but require a structured continental platform.

- The HAMES Network provides a practical mechanism to translate policy commitments into coordinated action and impact.

Call to Action

- AU Member States: Endorse and actively participate in the HAMES Network through designated national focal points.

- African Union Commission and RECs: Recognize HAMES as a technical coordination mechanism for F-SAMA and CAADP implementation.

- Development Partners and Technical Agencies: Support the Network through capacity development, knowledge exchange, and strategic investments.

Governance and Structure of the HAMES Network

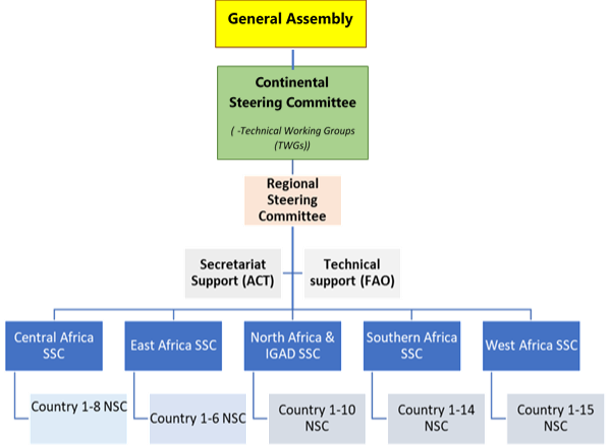

A. General Assembly

General Assembly of the Network will be composed of Heads of Agricultural Mechanization and/or Engineering Services from AU Member States or One official representative per Member State nominated by the government.

Role

- Supreme decision-making body of the Network

- Provides strategic direction and policy guidance

- Endorses work plans, reports, and major initiatives

- Approves amendments to statutes or operating procedures

Meetings

- Ordinary session: once every two years (aligned with major CAADP or AU agriculture events)

- Extraordinary sessions: as required

B. Continental Steering Committee (CSC)

A steering committee composing of:

- Chairperson

- Vice-Chairperson

- Regional Representatives (one per AU region: North, West, Central, East, Southern Africa and Horn of Africa)

- Immediate Past Chair (ex-officio)

Role

- Provides strategic oversight between General Assembly sessions

- Guides implementation of the Network’s work programme

- Ensures regional balance and coordination

- Represents the Network in high-level AU, REC, and partner engagements

Meetings

- At least twice per year (physical or virtual)

Chairperson and Vice-Chairperson

Selection

- Elected by the General Assembly

- Rotational basis to ensure regional equity

Roles

- Provide leadership and visibility to the Network

- Chair meetings of the General Assembly and Steering Committee

- Serve as principal spokespersons of HAMES

- Facilitate engagement with AUC, RECs, FAO, ACT, and development partners

C. Technical Working Groups (TWGs)

Composition

- Technical experts drawn from Member States

- Co-opted specialists from RECs, academia, private sector, and development partners (as appropriate)

Indicative Thematic Areas

- Mechanization Policy and Strategy

- Engineering Standards, Testing, and Quality Assurance

- Sustainable and Climate-Smart Mechanization (F-SAMA implementation)

- Mechanization Service Delivery and Business Models

- Digitalization, Data, and Knowledge Platforms (AfricaMechanize)

Role

- Provide technical inputs, guidelines, and knowledge products

- Support peer learning and capacity development

- Advise the Steering Committee on technical matters

D. Secretariat

Hosting Arrangement

- Hosted by a recognized continental or regional institution (e.g. ACT in collaboration with AUC/FAO), subject to endorsement by the General Assembly

Role

- Day-to-day coordination and administration of the Network

- Organization of meetings and communication

- Knowledge management and documentation

- Liaison with AUC, RECs, partners, and platforms such as AfricaMechanize

- Support monitoring, reporting, and resource mobilization

E. Regional Steering Committee (Focal Points)

Composition

- Designated institutions or individuals at REC or regional level

Role of the Regional Steering Committee on SAM

- Provide strategic oversight and guidance for the implementation of SAM at regional level.

- Ensure alignment of regional mechanization initiatives with F-SAMA, CAADP commitments, and continental priorities.

- Facilitate coordination among Member States within the region to promote harmonized policies and standards.

- Support monitoring and evaluation of regional mechanization activities and progress toward SAM targets.

- Advise on technical priorities and emerging mechanization issues, including climate-smart and inclusive practices.

- Promote knowledge sharing and peer learning between countries in the region.

- Strengthen partnerships with RECs, development partners, research institutions, and private sector actors.

- Guide resource mobilization and investment planning for regional SAM programs.

- Act as the regional liaison between national Heads of Mechanization and the continental HAMES Network.

- Ensure gender-responsive and youth-inclusive approaches in mechanization initiatives.

F. National Steering Committee NSC (Focal Points)

Composition

- Designated institutions or individuals at country level

Role

- Provide strategic oversight for the planning, coordination, and implementation of SAM initiatives at the national level.

- Ensure alignment of national mechanization policies and programs with F-SAMA and CAADP commitments.

- Facilitate cross-sectoral coordination between ministries, agencies, private sector, farmer organizations, and research institutions.

- Guide the development and prioritization of national SAM action plans, roadmaps, and investment programs.

- Oversee resource mobilization and ensure efficient allocation of funds for SAM initiatives.

- Monitor and evaluate the implementation progress, impact, and outcomes of national SAM interventions.

- Promote knowledge management and learning, including documentation and dissemination of best practices.

- Advocate for inclusive, climate-smart, and sustainable mechanization approaches that target smallholders, youth, and women.

- Ensure linkages between national SAM activities and regional/continental platforms, such as HAMES and AfricaMechanize.

- Serve as a decision-making forum for resolving operational, technical, and policy challenges related to mechanization.

G. Strategic Partners and Observers

Participants

- African Union Commission

- Regional Economic Communities

- FAO, development partners, research institutions, private sector associations

Role

- Provide technical, financial, and strategic support

- Participate as observers (non-voting)

- Align partner initiatives with HAMES priorities

Organizational Structure of the HAMES (organogram)

Functions and Activities of the HAMES Network

Some of the aligned set of functions and activities for the HAMES Network, focused specifically on Sustainable Agricultural Mechanization (SAM) and fully consistent with F-SAMA and CAADP are as provided below (Table 1.0):

Table 1.0. Functions and Activities of the HAMES Network

Segment | Function | Key Activities |

Policy Coordination and Strategic Advisory | Provide coordinated technical and policy guidance to AU Member States on sustainable agricultural mechanization. | · Facilitate peer review and exchange on national SAM and mechanization policies · Provide technical inputs to align national mechanization strategies with F-SAMA and CAADP commitments · Advise AUC and RECs on emerging policy issues, trends, and priorities in SAM · Support integration of SAM into national agriculture, climate, and industrial development strategies |

Operationalization of F-SAMA | Support practical implementation of the Framework for Sustainable Agricultural Mechanization in Africa. | · Translate F-SAMA pillars into actionable national and regional implementation pathways · Develop guidance notes, toolkits, and implementation checklists for SAM · Support Member States in identifying entry points and sequencing of SAM interventions · Share country experiences, lessons learned, and scalable models through peer learning mechanisms |

Technical Standards, Engineering Services, and Quality Assurance | Promote harmonized engineering standards and quality assurance for sustainable mechanization | · Exchange best practices on machinery testing, certification, and standards enforcement · Contribute to regional and continental guidelines on equipment safety, efficiency, and environmental performance · Strengthen the role of public engineering services in inspection, testing, and advisory functions · Support capacity development for national mechanization and engineering institutions |

sustainable and Climate-Smart Mechanization | Advance environmentally responsible, climate-smart, and resource-efficient mechanization pathways | · Promote SAM solutions aligned with climate-smart agriculture and conservation agriculture principles · Facilitate exchange on low-emission, energy-efficient, and renewable-energy-powered mechanization options · Support integration of SAM into NDCs, climate adaptation plans, and green growth strategies · Document and disseminate good practices on SAM for climate resilience |

Mechanization Service Delivery and Inclusive Business Models | Support inclusive, efficient, and market-oriented mechanization service delivery systems. | · Share experiences on mechanization service provision models (public, private, PPP, youth- and women-led) · Promote demand-driven and smallholder-appropriate mechanization pathways · Support development of guidelines for mechanization hire services and value-chain-based approaches · Facilitate linkages between public engineering services and private sector actors |

Knowledge Management, Data, and Digitalization | Strengthen evidence-based decision-making and knowledge exchange on SAM. | · Contribute national data, case studies, and policy updates to the AfricaMechanize Platform · Support development and use of SAM indicators for monitoring progress under CAADP and F-SAMA · Promote digital tools for planning, tracking, and reporting mechanization interventions · Facilitate documentation and dissemination of lessons learned and success stories |

Capacity Development and Professionalization | Enhance human and institutional capacity for sustainable agricultural mechanization. | · Identify capacity gaps among mechanization and engineering services · Support development of training curricula, short courses, and professional exchanges · Promote south–south and triangular cooperation on SAM skills and technologies · Strengthen professional networks among mechanization engineers and policymakers |

Advocacy, Partnerships, and Resource Mobilization | Enhance visibility, partnerships, and investment for SAM in Africa. | · Advocate for increased public and private investment in sustainable mechanization · Engage development partners and financial institutions on SAM priorities · Support coordinated resource mobilization aligned with F-SAMA and CAADP · Represent Member States’ technical perspectives in continental and global mechanization forums |

Monitoring, Learning, and Reporting | Support tracking of progress and continuous learning on SAM implementation. | · Contribute technical inputs to CAADP Biennial Review indicators related to mechanization · Support peer learning reviews on SAM implementation progress · Document lessons learned and adaptive practices across countries · Provide periodic technical reports to AUC, RECs, and partners |

HAMES Network Results Matrix on SAM

Aligned with AU results-based management, F-SAMA, and CAADP BR logic, HAMES Network’s role on SAM are provided in Result Matrix as expressed below (Table 2.0)

Table 1.0. HAMES Network Result framework Matrix

Function | Expected Outputs | Key Activities | Indicative Indicators |

Policy Coordination & Strategic Advisory | Harmonized and SAM-aligned mechanization policy guidance | § Peer review of national mechanization policies § Technical advisory inputs to AUC/RECs § Policy dialogue forums among Heads of Services | § Number of countries supported with policy alignment § Number of policy dialogues convened § References to HAMES inputs in AU/REC policy documents |

Operationalization of F-SAMA | Practical F-SAMA implementation pathways adopted by Member States | § Develop F-SAMA implementation guides § Support national SAM roadmap § Exchange lessons and good practices | § Number of countries with F-SAMA-aligned action plans § Number of guidance tools developed and used § Number of peer-learning events held |

Standards, Engineering Services & Quality Assurance | Improved harmonization of mechanization standards and engineering services | § Exchange on machinery testing and certification § Develop technical guidelines § Capacity strengthening of engineering services | § Number of countries applying harmonized standards § Number of technical guidelines produced § Number of institutions strengthened |

Sustainable & Climate-Smart Mechanization | Increased adoption of climate-smart and environmentally responsible mechanization | § Promote SAM–CSA linkages § Share low-emission and energy-efficient technologies § Integrate SAM into climate strategies | § Number of countries integrating SAM into NDCs/CSA plans § Number of SAM climate-smart practices documented § Evidence of reduced environmental risks |

Mechanization Service Delivery & Inclusive Business Models | Strengthened, inclusive mechanization service delivery systems | § Exchange on hire services and PPP models § Promote youth- and women-inclusive models § Develop service delivery guidelines | § Number of service delivery models documented/adopted § Number of countries promoting inclusive mechanization services § Uptake of guidelines by Member States |

Knowledge Management, Data & Digitalization | Improved availability and use of SAM data and knowledge | § Populate AfricaMechanize Platform § Share case studies and country profiles § Promote use of SAM indicators | § Number of countries contributing data to AfricaMechanize § Number of knowledge products published § Use of SAM data in planning/reporting |

Capacity Development & Professionalization | Enhanced technical and institutional capacity on SAM | § Identify capacity gaps § Support training and professional exchanges § Promote south–south cooperation | § Number of training events supported § Number of professionals engaged in exchanges § Reported improvements in institutional capacity |

Advocacy, Partnerships & Resource Mobilization | Increased visibility and investment for SAM | § Joint advocacy initiatives § Partner engagement and coordination § Support resource mobilization efforts | § Number of advocacy events conducted § Number of partnerships formalized § Amount of resources mobilized or leveraged |

Monitoring, Learning & Reporting | Strengthened tracking and learning on SAM implementation | § Technical inputs to CAADP Biennial Review § Peer learning reviews § Periodic technical reports | § Quality of mechanization-related BR reporting § Number of learning reports produced § Evidence of adaptive improvements |